Some call it smart downsizing. Others think it’s just plain cool. A home that once held cargo now promises a fresh way to live. At least, that’s how it starts. Over time, some cracks begin to show—literally and otherwise. Here are ten container home realities people rarely talk about.

Extreme Temperature Swings

Metal walls trap heat in summer and become icy cold in winter, making climate control a constant struggle. Insulation helps, but it also eats up precious space inside. Interestingly, some homeowners combat this issue by installing green roofs that naturally regulate temperature.

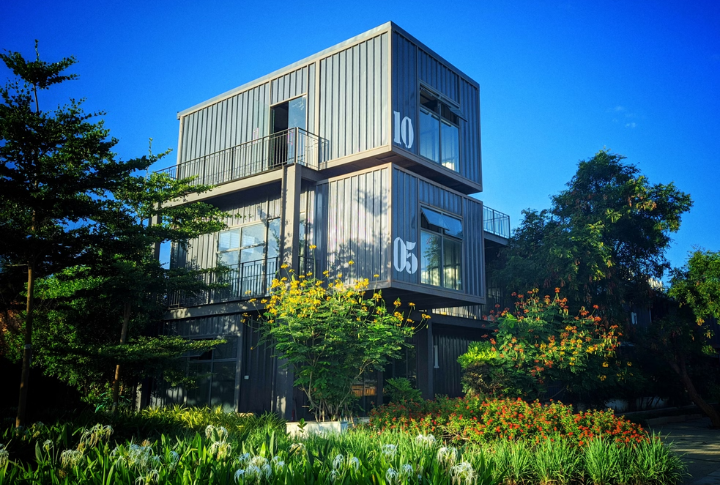

Limited Space And Layout Challenges

With only 8 feet of width, arranging furniture feels like solving a tricky puzzle. While stacking containers vertically adds space, it comes with high reinforcement costs. To work around these limitations, some owners opt for movable walls, which create flexible and adaptable layouts.

Permitting And Zoning Nightmares

In many areas, container homes face strict regulations since they don’t fit traditional housing codes. Because of this, permits can take months to secure—or worse, might not be granted at all. Surprisingly, some cities ban container homes outright due to aesthetic concerns.

Rust And Corrosion Issues

Despite their industrial design, shipping containers corrode quickly in humid environments. To combat rust, regular maintenance and protective coatings are essential. A fascinating solution some homeowners use is ship-grade paint, which significantly slows down metal decay.

Acoustic Problems

Unlike traditional homes, metal walls do little to block out noise, often making the space uncomfortably loud. Some homeowners resort to egg cartons for a budget-friendly fix. While soundproofing materials can help, they come with added costs and take up valuable space.

Metal Expansion Can Warp The Structure

Changes in temperature cause metal to swell and shrink, which can gradually distort the structure’s shape. This movement may affect doors, windows, or panel alignment, causing unexpected gaps or difficulty closing things. Some builders use flexible joints or sliding connections to absorb this stress, but it’s still a hidden engineering headache.

Structural Modifications Are Costly

Want to add a window or door? Cutting into a container’s metal walls can weaken the structure, making reinforcement necessary. The process requires special welding and expert planning to avoid safety issues. To sidestep this challenge, some owners opt for glass walls instead.

Difficult Resale Market

Selling a container home can be tricky since conventional buyers hesitate due to its unique design. On top of that, banks frequently refuse mortgages for these properties, further limiting demand. Instead of selling, homeowners typically turn their space into popular Airbnb rentals.

Plumbing And Electrical Challenges

Running pipes and wiring through steel walls takes extra planning and specialized tools that eventually increase costs. Standard installations don’t always work, forcing builders to rethink their approach. Off-grid homeowners sometimes use solar-powered plumbing systems to bypass traditional setups.

Condensation And Moisture Problems

Humidity inside a container home can quickly lead to mold, which affects air quality and overall health. Proper ventilation is essential, but it adds an extra expense to construction. A creative yet simple solution some homeowners swear by is placing charcoal bags around the home to absorb excess moisture.